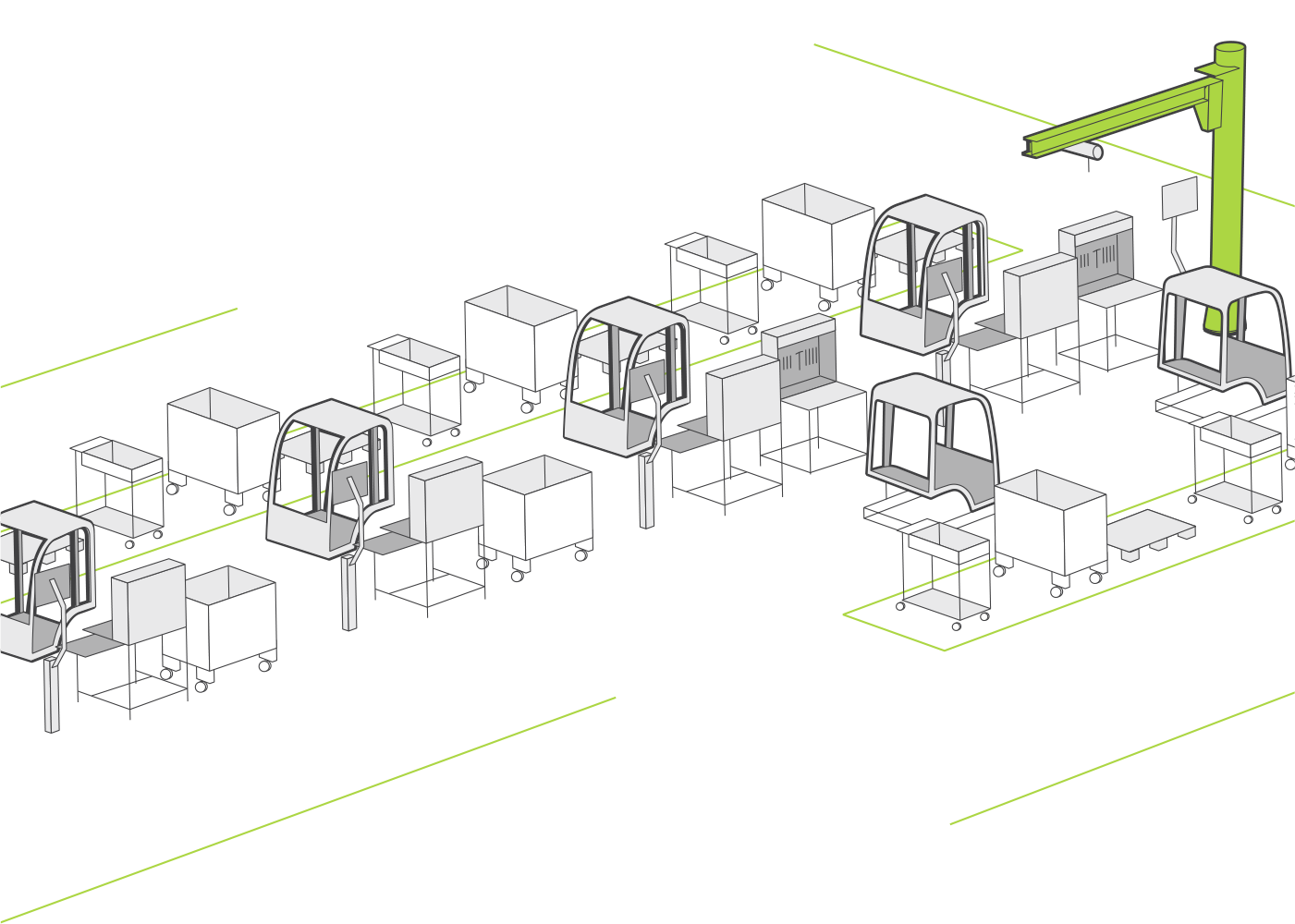

Process Chain

From the concept to the design the project, up to the development and implementation of series production, the entire process chain is designed and optimized for the creation of cabins that meet the highest quality standards.

Design

Functionality, ergonomics, usability and aesthetics: we can design the best product for you or follow your instructions in a joint design process, defining objectives and timeframes for each step of the process.

Development

We combine your needs with the features of the machine that host the cabin, following a project development which includes all the features the finished product will have, in a rational way. We use 4 CAD applications to meet all design needs, even the most special.

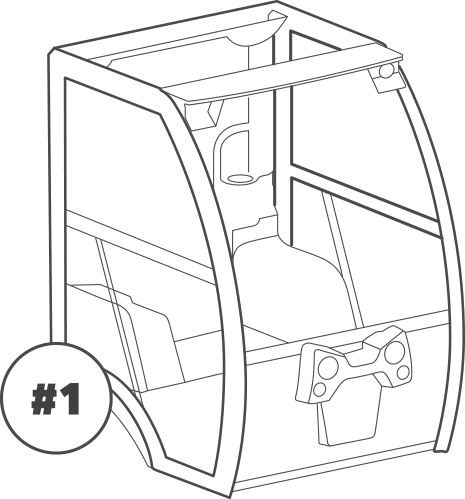

Prototype

and mock-up

We create a totally functional prototype of the cabin suitable for approval tests, then we perform tests and apply modifications and improvements, up to the final Model no. 1 ready for industrialization.

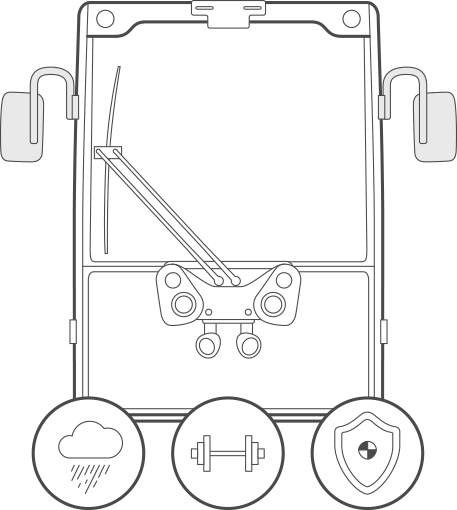

Approval and Testing

The approval and testing phase includes a constant series of tests on the cabin, to ensure compliance with quality and safety standards. Through simulations we validate: structural strength, safety of driver’s cabin, ergonomics, comfort and functionality based on choices that are dictated also by the experience we gained in over 40 years in the field.

Industrialization

The industrialization process takes place through the standardization of all processes (purchases, acceptance, production, and testing) and inspections. During the industrialization process the necessary equipment to ensure series production is also validated and completed.

Supplier management

We manage purchase flows, business negotiations, and definition of specifications together with the suppliers, in order to achieve the MMS targets agreed.

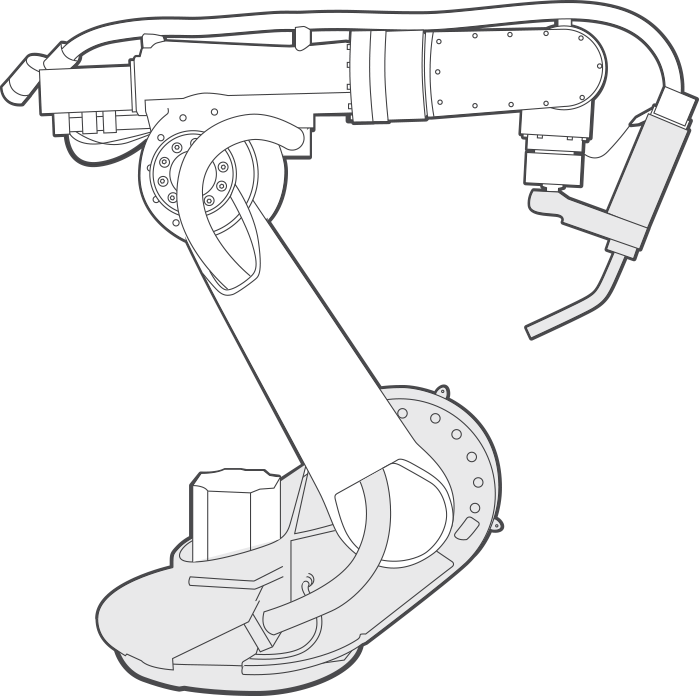

Production

We manage each stage of the production process for the manufacturing of cabins: from raw material procurement to assembly, and final functional testing. All are monitored according to the ISO 9001:2008 quality system.

read more

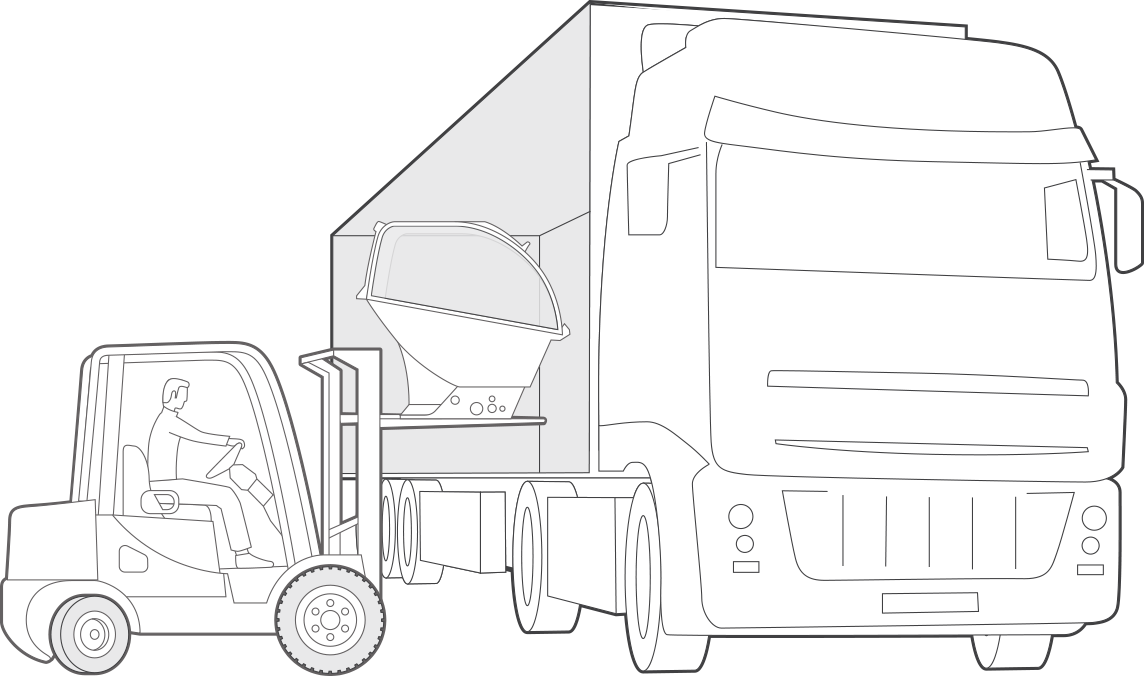

Logistics

We do not stop at the simple product manufacture, we also support you in the later stages through planning and logistics services.

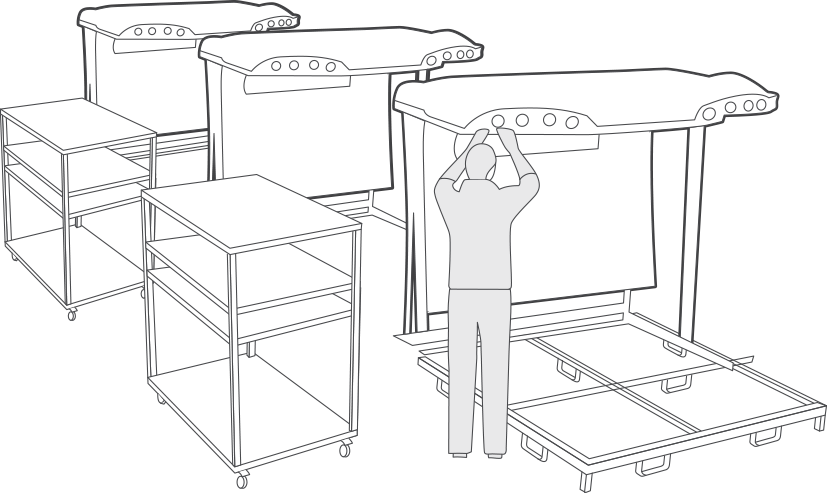

Implementation of assembly lines

Our specific competence in the world of cabins make us the ideal advisors to assist in the design of the lines.